- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

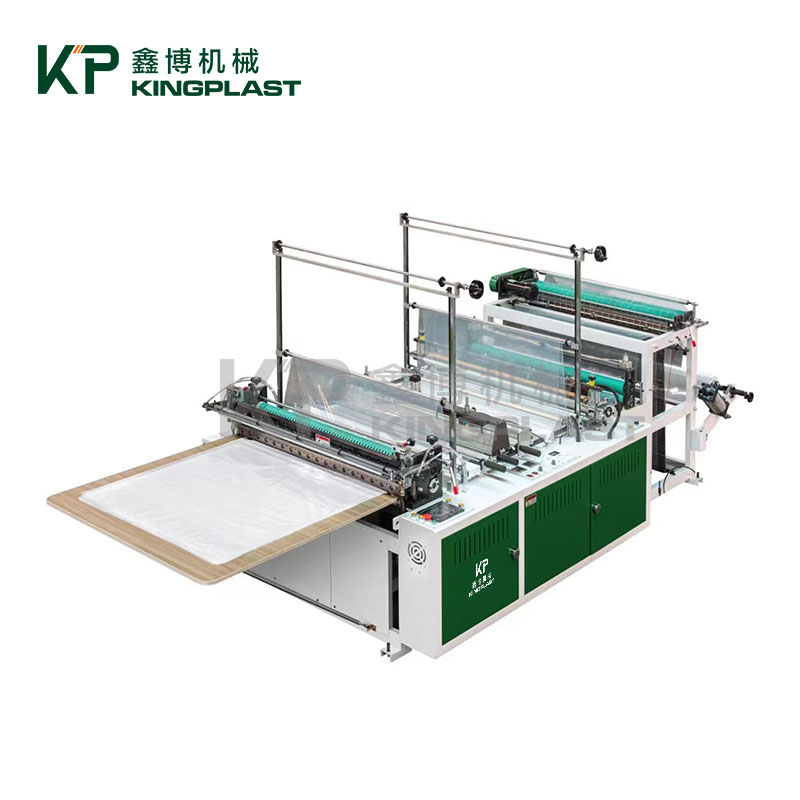

Flat Bottom Bag Making Machine

Ruian Kingplast Machinery Co., Ltd have more than 15years experience to work with flat bottom bag making machines. It’s specifically designed for producing flat bottom bags that are suitable for various applications such as big size package bags, medical garbage bags, and packaging for metals, plastics, and hardware items. In industrial production, flat bottom bags are considered essential packaging materials due to their versatility and functionality. Ruian Kingplast Machinery Co., Ltd specializes in manufacturing high-quality flat bottom bag making machines to meet the diverse packaging needs of industries.

Send Inquiry

Optional Equipment:

1.EPC

2.Auto tension

3. Air shaft

4. Yaskawa/Panasonic servo motor

6. Auto feeding

7. Conveyor

Kingplast FLAT BOTTOM BAG MAKING MACHINE introduce:

Customization options offered by Kingplast to meet the specific demands of customers further add value to their services. The ability to tailor the flat bottom bag making machines according to individual requirements can greatly benefit businesses looking for specialized solutions.

With Kingplast's commitment to promptly addressing customer inquiries and providing customized solutions, they indeed is a good option for those interested in purchasing flat bottom bag making machines. Potential buyers can reach out to Kingplast for more information and discuss their specific needs for a tailored solution.Ruian kingplast machinery co.,ltd’s hot sealing cold cutting flat bottom bag machine have two designs,but difference film thickness request different machine design.

The first type is flat bottom bag making machine suit for single layer film thickness 5 micron to 10 microns,this kind flat bottom bag making machine usually for produce food package bag ,shopping bags ,daily necessities package bag,grocery bags, garment packing bags,etc

The second type is heavy duty flat bottom bag making machine suit for thickness 20micron to 60micron,as normal use for produce packaging bags like dust bags, and heavy duty garbage bags. It is equipped with a hot sealing knife and a cold cutting knife, which are heavy and made of stainless steel to ensure durability and reliability.

Technical Parameters:

|

Model |

GFQ-600 |

GFQ-800 |

GFQ- 1000 |

GFQ- 1200 |

|

Max.Width of bag-making(mm ) |

550 |

750 |

950 |

1150 |

|

Max.Length of bag-making(mm) |

950 |

950 |

1200 |

2000 |

|

Speed of bag-making(pc/min) |

30- 120 |

30- 100 |

30- 100 |

30-80 |

|

Power of main motor(kw) |

1.5 |

1.5 |

1.5 |

1.5 |

|

Weight(kg) |

750 |

800 |

900 |

1000 |

|

Outline dimension (L×W×H) mm |

3200×1150×1550 |

3200×1350×1650 |

3200×1550×1750 |

3400×1750×1850 |

|

Heating power (kw) |

2 |

3 |

4 |

4 |

Machine Detail: