- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

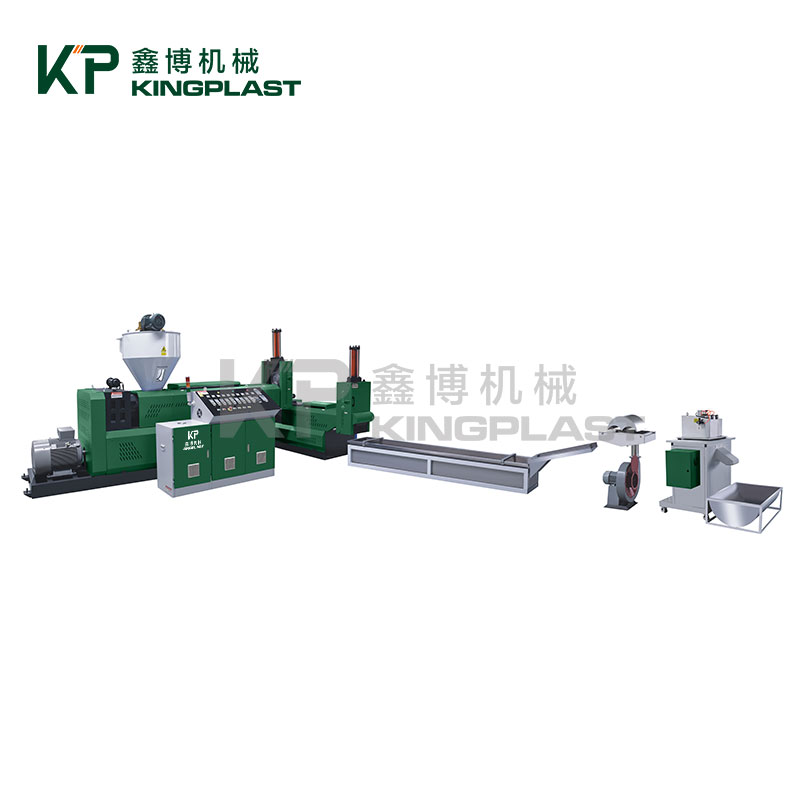

Two Stage Pelletizer Machine

You can rest assured to buy Two Stage Pelletizer Machine from KINGPLAST factory and we will offer you the best after-sale service and timely delivery.

Send Inquiry

Ruian Kingplast Machinery Co., Ltd. is a leading provider of plastic packaging solutions. We prioritize environmental concerns and offer our customers a pelletizer machine specifically designed for recycling film waste. This innovative machine enables the recycling and granulation of waste plastic film, leading to reduced production costs and significant contributions to environmental protection. Our two-stage pelletizer machine is an advanced development based on the one-stage pelletizer machine.

In comparison to the one-stage pelletizer machine, the two-stage pelletizer machine offers higher output capabilities. This means that more plastic film can be processed and recycled, resulting in increased efficiency and productivity for our customers. By investing in our two-stage pelletizer machine, customers can achieve greater production volumes while maintaining excellent quality in their recycled plastic pellets. This not only reduces their overall production costs but also promotes sustainable practices by minimizing waste and maximizing resource utilization.

kingplast Two stage pelletizer machine introduce:

As one of the renowned manufacturers and suppliers of Two stage pelletizer machines in China, Kingplast prioritizes product quality as the foundation of our development. We firmly believe in providing excellent after-sales service to ensure that our customers have complete confidence in both our product quality and support.

At Kingplast, we are committed to delivering high-quality machines that meet the industry's standards and exceed customer expectations. Our Kingplast team of experts rigorously tests and inspects each machine before it leaves our facility, guaranteeing its reliability and performance.

In addition to our Kingplast dedication to product quality, we place great importance on after-sales service. Our customer support team is readily available to address any inquiries or concerns that our customers may have. We Kingplast strive to provide timely assistance and effective solutions, ensuring that our customers have a seamless experience throughout the entire product lifecycle.

The Two stage pelletizer machine is an economical and ideal choice for customers aiming to establish a recycling raw material factory. It offers a highly efficient solution for processing waste materials generated by film blowing machines.

The operation of the Two stage pelletizer machine is straightforward. The waste material is fed into the machine through the designated feed port. Inside the machine, the screw heats and plasticizes the material, preparing it for further processing. The plasticized material is then extruded from the die head and enters a water cooling storage system. This helps to cool and solidify the material for easier handling. Finally, the material reaches the cutter machine. The cutter machine knives work together to cut the plasticized material into small pieces, achieving the desired pelletized form.

The simplicity in design and operation of the Two stage pelletizer machine makes it user-friendly and efficient for recycling waste materials. It provides an effective solution for transforming waste plastic film into reusable raw materials.If you have any further inquiries or require more detailed information about the Two stage pelletizer machine, please feel free to contact Kingplast. We are here to assist you and provide the necessary support.

Two Stage Pelletizer Machine Parameter:

|

Model |

KP-D 90 |

KP-D100 |

KP-D110 |

KP-D120 |

KP-D140 |

|

Diameter of Screw Stem |

90/100mm |

100/100mm |

110/110mm |

120/110mm |

140/130mm |

|

L:D |

20:1/12:1 |

20:1/12:1 |

20:1/12:1 |

20:1/12:1 |

20:1/12:1 |

|

Speed of Screw |

10-110rpm |

10-110rpm |

10-110rpm |

10-110rpm |

10-110rpm |

|

Gearbox |

180/173 |

180/173 |

180/173 |

200/173 |

225/180 |

|

Motor Power |

22kw/15KW |

22kw/15KW |

37kw/15KW |

37kw/18.5KW |

55kw/22KW |

|

Output |

110kg/h |

130kg/h |

150kg/h |

180kg/h |

220kg/h |

|

Water Tank Length) |

2800mm Stainless |

||||

|

Screen changer |

Hydraulic for both screw |

||||

|

Screen changer hole |

6mm |

||||

|

Die head hole(Alloy Metal) |

4mm |

||||

|

Cutter Knife |

Hobbing Cutter(Alloy Steel) |

||||

|

Cutter Motor |

2.2kw |

2.2kw |

3kw |

3kw |

3kw |

|

Machine Weight |

2.4t |

2.6t |

2.8t |

3t |

4t |

|

Overail Dimensions |

8.8*1.5*1.1m |

9*1.3*1.2m |

9.2*1.3*1.3m |

9.6*1.4*1.3m |

9.6*1.5*1.3m |

Machine Detail: