- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

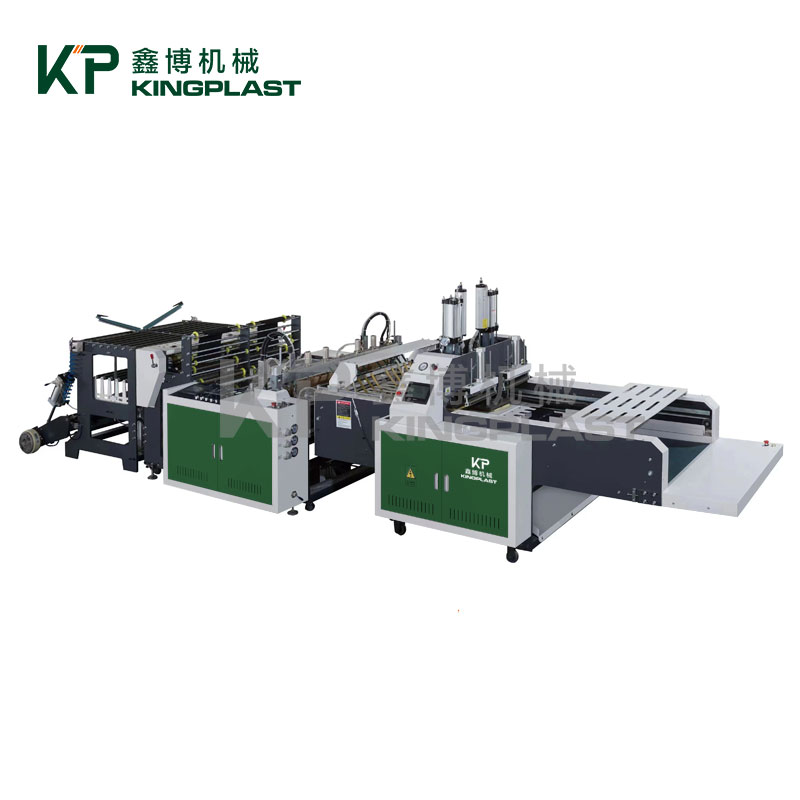

Flat Bottom Garbage Bag Making Machine

Ruian Kingplast Machinery Co., Ltd Flat Bottom Garbage Bag Making Machine is kind of bottom sealing cold cutting bag making machine . This machine produce garbage bags suit for daily living and medical waste garbage bags.Garbage Bag Making Machine can make according to customer’s different size and thickness requirement. Kingplast always insist on good quality and good after sale service to make sure customer no worry about buying machines from us from any step .Welcome you to work with us at any time.

Send Inquiry

Optional Equipment:

|

1. EPC |

2. Auto tension |

|

3. Air shaft |

4. Yaskawa/Panasonic servo motor |

|

5.Auto feeding |

6. Conveyor |

Sample Picture

Kingplast Flat Bottom Garbage Bag Making Machine introduce:

1.Kingplast Flat Bottom Garbage Bag Making Machine Feeding System:

Manual Film Feeding: The machine allows manual loading of the film onto the feed roller. Users can choose between a normal shaft or an air shaft for this process.

Feed Speed Control: The feeding system incorporates an AC motor that operates in conjunction with an inverter for precise control over the feed speed.This feature ensures flexibility and adaptability to different production requirements.

2.Kingplast Flat Bottom Garbage Bag Making Machine Main Host:

Garbage Bag Making Machine Main Motor: The main motor driving the core functions of the machine is a reducer motor.

Material Feeding: The material feeding process is managed by a Chinese servo motor.

Customers have the option to customize and request a high-quality brand servo motor if they desire superior performance.

Max bag width decide garabge bag machine model ,bag length and working speed can be adjusted by computer .Bags after sealing by copper knife,then be cutted by steel knife .

3.Kingplast Flat Bottom Garbage Bag Making Machine Collect Table:

Material Support: The collect table is constructed from wood and serves as a stable platform for handling the produced garbage bags.

Size Adaptability: Recognizing the need for accommodating larger bag sizes, the collect table is designed to be larger to meet the specific requirements of the machine. This ensures that the machine is capable of handling and collecting bags of varying dimensions.

Technical Parameters:

|

Model |

GFQ-600 |

GFQ-800 |

GFQ-1000 |

GFQ-1200 |

|

Max.Widthofbag-making(mm) |

550 |

750 |

950 |

1150 |

|

Max.Lengthofbag-making(mm) |

950 |

950 |

1200 |

2000 |

|

Speedofbag-making(pc/min) |

30- 120 |

30- 100 |

30- 100 |

30-80 |

|

Powerofmainmotor(kw) |

1.5 |

1.5 |

1.5 |

1.5 |

|

Weight(kg) |

750 |

800 |

900 |

1000 |

|

Outlinedimension (L×W×H)mm |

3200×1150×1550 |

3200×1350×1650 |

3200×1550×1750 |

3400×1750×1850 |

|

Heatingpower(kw) |

2 |

3 |

4 |

4 |

Machine Detail: