- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

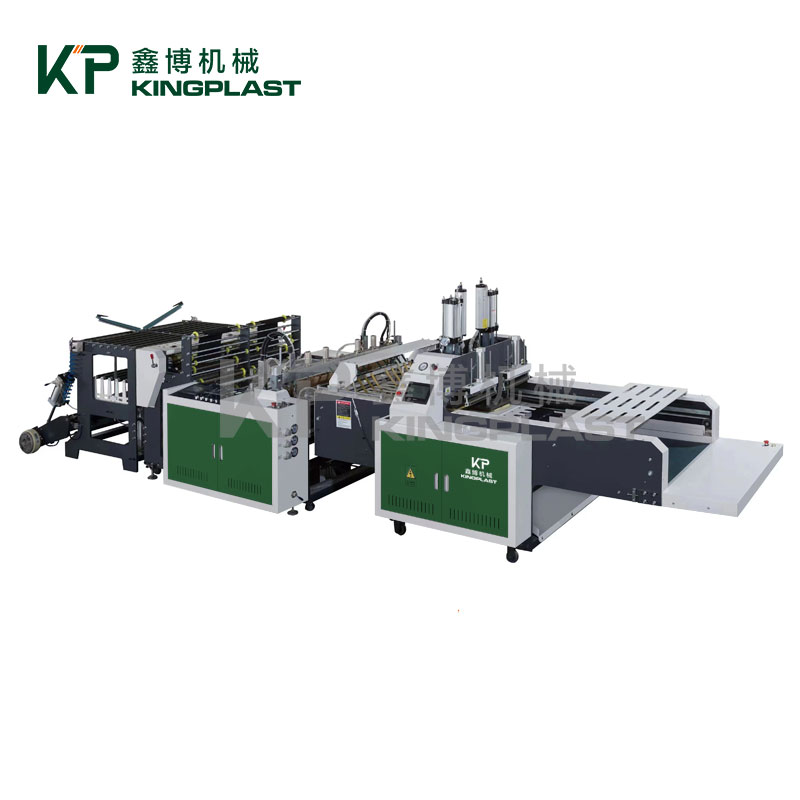

Gift Bag Making Machine

KINGPLAST as the professional manufacturer, we would like to provide you high quality Gift Bag Making Machine. And we will offer you the best after-sale service and timely delivery.

Send Inquiry

Optional Equipment:

|

1. EPC |

2. Auto tension |

|

3. Air shaft |

4. Yaskawa/Panasonic servo motor |

|

5.Butterfly or special sharp Punchers |

6. Folding device |

|

7.Automatic collection table |

8.Ultrasonic device |

BAG SAMPLE

RUIAN KINGPLAST MACHINERY CO., LTD produce OPP type Gift Bag Making Machine which is widely use for package in daily life .This gift bag making machine is also named side sealing bag making machine ,can pack pen ,auto parts ,cosmetics, christmas gift and so on .If need make any size and design ,we can make all according to your demand ,you are welcome to place order at any time . 24hours service line wait for you .

Kingplast Gift Bag Making Machine can make bottom gusset ,top sealing ,hand punch like our sample bag photos showed .These design are very popular on the market to pack gift .If you have different idea for design ,also can let us know it .

Kingplast Gift bag making machine description :

1.Kingplast Gift Bag Making Machine Feeding System:

The machine is equipped with a manual film feeding system, where film rollers are loaded onto a standard shaft by operators.

The feeding speed is controlled by an AC motor in collaboration with an inverter for precise adjustments.

Optional features include an EPC (Edge Position Control) device and a folding device, providing added functionality based on user preferences.

EPC, which stands for edge position control, is a technology utilized in the transmission process. It actively corrects any deviations in the direction of the coil raw material, ensuring real-time testing, tracking, and correction.

2.Kingplast Gift Bag Making Machine Host Parts:

Key components of the machine include a bottom gusset, a double-sided tape device, a standard punching device with a 5mm hole size, a flat knife, and a knurl knife.

The main motor driving the machine is a reducer motor, providing reliable power for seamless operation.

Precise control over the feeding speed is achieved through a step motor or servo motor.

The computerized system allows users to adjust the cutting bag width and working speed according to their specific requirements.

3.Kingplast Gift Bag Making Machine Collection Table:

The standard collection table is crafted from wood, providing a stable surface for gathering produced bags.

For enhanced automation, users have the option to integrate a conveyor belt or an automatic collection table into the system based on their specific needs.

Technical Parameters:

|

Model |

RQL-600 |

RQL-800 |

RQL-1000 |

|

Length of sealing&cutting(mm) |

60-580 |

80-780 |

90-980 |

|

Width of sealing&cutting(mm) |

50-600 |

55-600 |

60-600 |

|

SpeedofBag-making(pcs/min) |

40-200 |

40-200 |

40-120 |

|

Accuracyoffinishedproduct |

±0.3 |

±0.3 |

±0.3 |

|

Main motor (kw) |

1.1 |

1.5 |

1.5 |

|

Totalpower |

4 |

5 |

6 |

|

Weight |

800 |

1000 |

1100 |

|

DimensionL*W*H(mm) |

3600x1150x1700 |

3600x1350x1700 |

3600x1550x1700 |

Machine Detail: