- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

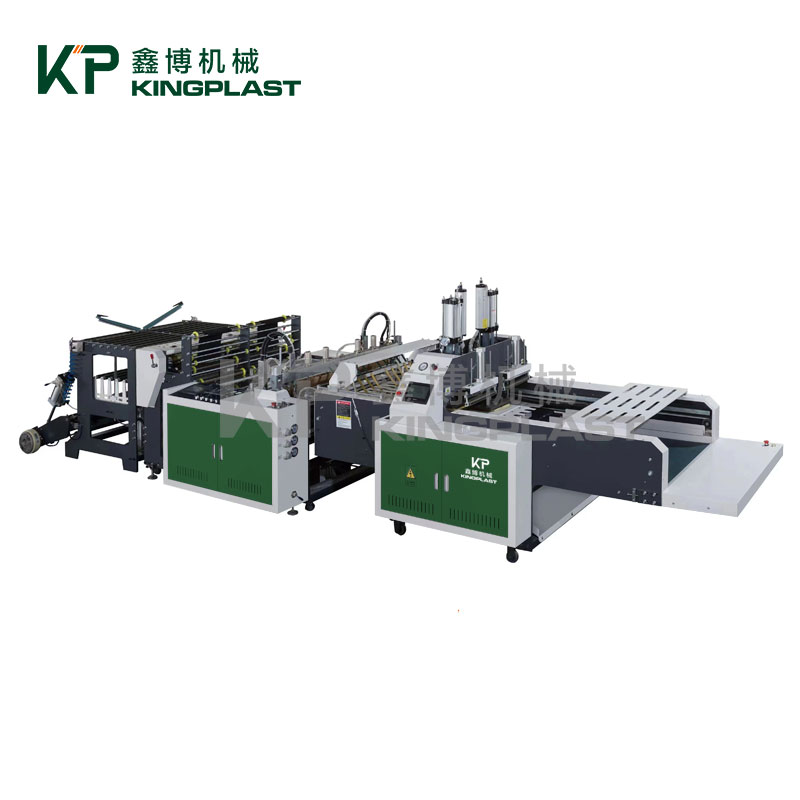

High Speed Tshirt Bag Making Machine

RUIAN KINGPLAST MACHINERY CO., LTD is a reputable manufacturer can customized plastic packaging solutions to meet customer's specific requirements .At present ,labor high cost is big reason to make customer request high speed machine .The High speed Tshirt bag making machine updated by our normal speed automatic T-shirt bag making machine,and very welcomed by customers.

Send Inquiry

RUIAN KINGPLAST MACHINERY CO., LTD prides itself on its customer-centric approach. We prioritize understanding the specific customer’s requirements then strive to deliver tailored plastic packaging solutions. The development of the high-speed T-shirt bag making machine exemplifies their commitment to meeting the evolving needs of their customers in terms of quality, output, and overall efficiency. Any customer's special demand will get kingplast high attention ,feel free to contact with kingplast to place order .

High speed Tshirt bag making machine use high quality electricity parts,such yaskawa servo motor ,schnaider low-voltage electricity part ,Omron temperature controller ,delta inverter etc. features:

High-speed operation: High-speed T-shirt bag making machines are designed for efficient production, with speeds typically ranging from 100 to 600 bags per minute. The high-speed operation significantly increases productivity and allows for more effective bag production.It’s air cylinder feeding system makes loading the roller film easier and safer for workers. The larger feeding roller diameter is designed to match the high-speed running, ensuring smooth and continuous feeding of the film.

Control panel and settings: High-speed T-shirt bag making machines are equipped with user-friendly control panels, enabling operators to set various parameters. These parameters include bag length, cutting speed, temperature etc. Operators have precise control over the production process, ensuring consistent and accurate bag production.

Technical Parameters:

|

Model |

KP- 400x2HS |

KP-500X2HS |

|

Max.Width of bag-making(mm ) |

380*2 |

450*2 |

|

Max.Length of bag-making(mm) |

350-700 |

350-700 |

|

Speed of bag-making(pc/min) |

150-300*2 |

150- 300*2 |

|

Main servo(kw) |

1.5 |

1.5 |

|

Feeding servo (kw) |

4 |

4 |

|

Punch servo (kw) |

1.3 |

1.3 |

|

Total power (kw) |

13 |

17 |

|

Weight(kg) |

2300 |

2500 |

|

Air compressor(hp) |

10 |

10 |

|

Outline dimension (L×W×H) mm |

6800×1350×1750 |

6800×1550×1800 |

Machine Detail: