- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

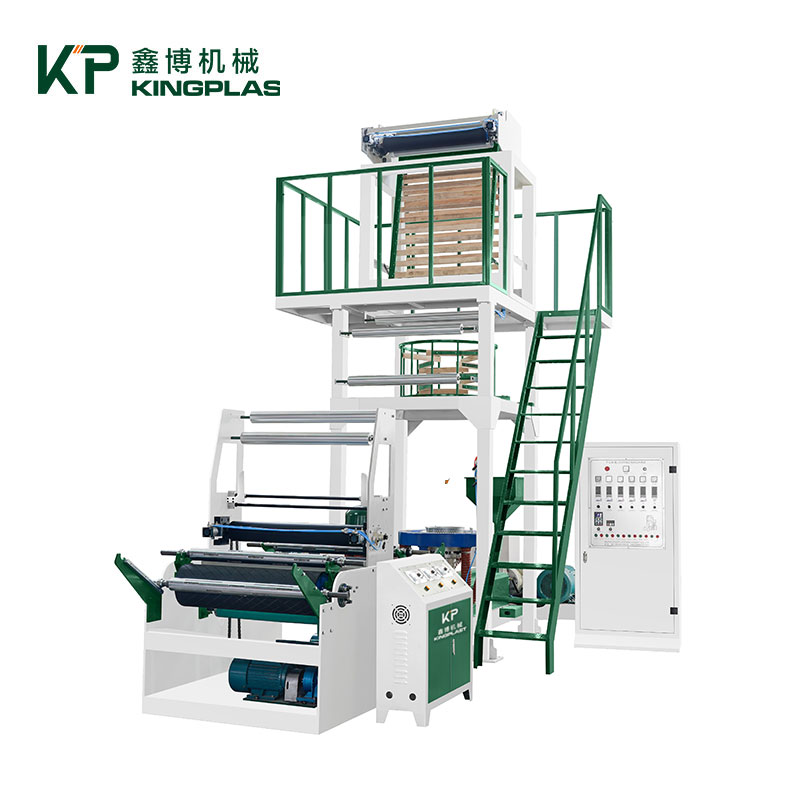

KP-N Film Blowing Machine with Online Printer

Ruian Kingplast Machinery Co., Ltd. is dedicated to meeting customer demands for film blowing machines with an innovative approach. The company has introduced a new design to incorporate a one-color printer that works seamlessly with the film blowing machine.

Send Inquiry

Optional Equipment:

|

1. Auto-loader |

2. Corona treater |

|

3. Rotary die head |

4. Double winder |

|

5. High speed screen changer |

|

Ruian Kingplast Machinery Co., Ltd. is dedicated to meeting customer demands for film blowing machines with an innovative approach. The company has introduced a new design to incorporate a one-color printer that works seamlessly with the film blowing machine. This addition is aimed at satisfying customer needs for simple logo printing on films. The online print unit is cost-effective, helping customers meet their printing requirements while saving on costs.

Kingplast Film blowing machine with online printer Features:

Responsive Customer Service:

The company ensures quick and efficient customer service by responding to every request within 24 hours.

Low Production Cost:

Film blowing machine with online printer is a cost-effective solution, making it an ideal choice for businesses starting operations or those with limited budgets. The streamlined process requires fewer machinery and equipment, leading to reduced operating expenses.

Easy Operation:

The film blowing machine with online printer features simple controls and a straightforward operating panel. This design is especially beneficial for new customers, allowing them to quickly learn and operate the equipment effectively.

Film Blowing Machine with Online Printer Components:

Extruder:

Components include the screw and barrel, main motor, die head, and air blower

Take-Up Unit:

Options for the take-up unit include rubber roller + Embassy roller, rubber roller + steel roller, and reducer + torque motor.

Winder Unit:

Winder unit components consist of rubber roller + steel roller, banana roller, with speed control achieved through a torque meter or inverter.

Electricity Box:

The electricity box houses temperature controllers, inverters for the main motor and take-up, ammeter, and voltmeter.

This film blowing machine with an online printer is designed to offer a comprehensive and efficient solution for film production with the added capability of logo printing. The emphasis on low production costs and easy operation makes it an attractive option for businesses looking to enter or optimize their operations in the film manufacturing industry.

Kingplast Normal film blowing maxhine parameter:

|

Model |

KP-N45 |

KP-N50 |

KP-N55 |

KP-N60 |

KP- N65 |

||

|

Suitable material |

HDPE LDPE LLDPE |

||||||

|

Film width(mm) |

100-500 |

300-600 |

400-800 |

500-1000 |

600-1200 |

||

|

Film thickness(mm) |

HD |

0.009-0.05 |

0.009-0.15 |

||||

|

LD |

0.02-0.15 |

0.03-0.15 |

|||||

|

Max.Extrusion output(kg/hr) |

HD |

35 |

40 |

50 |

55 |

65 |

|

|

LD |

40 |

45 |

60 |

70 |

80 |

||

|

Extruder |

|||||||

|

Screw diameter(mm) |

φ45 |

ф50 |

ф55 |

Ф60 |

ф65 |

||

|

Screw L/D length |

30:1/32:1 |

||||||

|

Screw material |

Bimetallic |

||||||

|

Cylinder material |

SACM-645/38CRMOALA |

||||||

|

Cylinder cooling |

250wx2 |

250wx2 |

370wx2 |

370wx3 |

550wx2 |

||

|

Driving motor(kw) |

11 |

15 |

18.5 |

22 |

30 |

||

|

Temperature control |

3 |

3 |

3 |

3 |

4 |

||

|

Type of die |

|||||||

|

Die size(mm) |

HD |

ф60/80 |

ф80/100 |

ф100/120 |

ф100/120 |

ф100/150 |

|

|

LD |

ф100/120 |

ф120/150 |

ф180/200 |

Ф200/220 |

ф220/ 250 |

||

|

Temperature control |

3 |

||||||

|

Air ring |

1 pcs |

||||||

|

Air blower(kw) |

2.2 |

3 |

3 |

4 |

5.5 |

||

|

Center steady stick |

1 |

|

|||||

|

Take-up unit |

|||||||

|

Roller width(mm) |

ф165×600 |

ф165×700 |

ф165×900 |

ф165×1100 |

ф165×1300 |

||

|

Height adjustable type |

/ |

||||||

|

Take-up speed(m/min) |

10-100 |

10-100 |

10-80 |

10-80 |

10-80 |

||

|

Take-up motor(kw) |

0.75 |

1.5 |

1.5 |

1.5 |

2.2 |

||

|

Winding unit |

|||||||

|

Type |

Surface friction type |

||||||

|

Winding motor(N.m) |

10 |

10 |

10 |

16 |

16 |

||

|

Winding speed(m/min) |

10-100 |

10-100 |

10-80 |

10-80 |

10-80 |

||